TM 5-3895-373-34

Table 2-6. Hopper Lift System Troubleshooting - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

4.

AUXILIARY HYDRAULIC SUPPLY TO VIBRATION AND CYLINDER CIRCUITS FAULTY.

WARNING

Hydraulic oil can be moderately flammable and can be an irritant to skin, eyes, and

respiratory system. Avoid prolonged exposure. Eye protection and rubber gloves

must be worn when working with hydraulic oil.

Step 1.

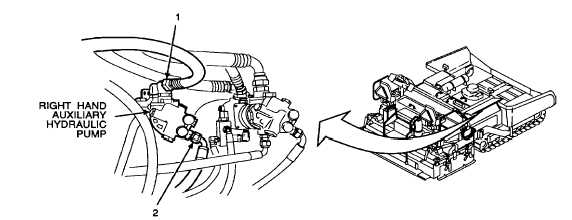

Open right access door per TM 5-3895-373-10. Remove right access cover per TM 5-3895-373-

10.With paving machine off per TM 5-3895-373-10, check right hand auxiliary hydraulic system

suction lines at (1) using hand pump per TM 9-4940-468-14.

Replace or repair components (auxiliary hydraulic system suction hoses, lines, and fittings per

paragraph 2.54, hydraulic reservoir components per paragraph 2.53) as necessary.

NOTE

The following test requires use of a hydraulic system tester. Install tester in-line at flow test point

indicated by each individual test per TM 9-4940-468-14. Make sure ratings of all fittings and hoses

used are adequate for maximum pressures and flows being tested.

Step 2.

Start paving machine per TM 5-3895-373-10. Install hydraulic system tester at port (2) for flow test

per TM 9-4940-468-14. Check flow at right hand auxiliary hydraulic pump discharge port (2).

Measure flow rate at 2475 ±25 psi (17 066 ±172 kPa) with engine at 2640 ±40 rpm.

If flow rate is less than 5 gpm (19 l/min), replace/repair right hand auxiliary hydraulic pump per

paragraph 2.42.

If flow rate is at least 5 gpm (19 l/min), replace right auger/conveyor flow divider per paragraph

2.55 and repair per paragraph 2.49.

Step 3.

Disconnect hydraulic system tester per TM 9-4940-468-14. Reconnect all hydraulic lines. Install

right access cover per TM 5-3895-373-10. Close right access door per TM 5-3895-373-10.

2-45