TM 5-3895-373-34

D.

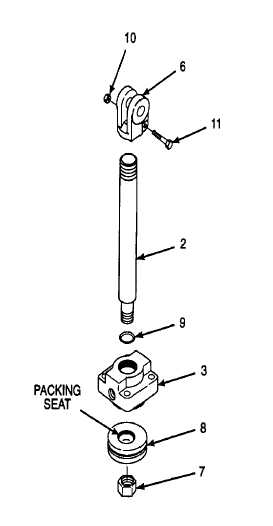

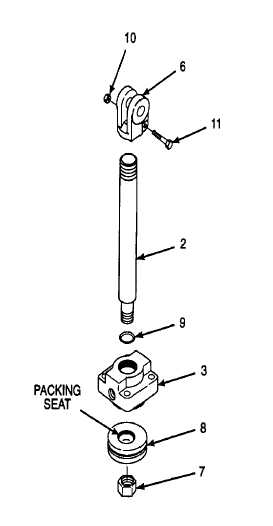

ASSEMBLE - Continued.

3.

ASSEMBLE PISTON COMPONENTS.

a.

Install and hand tighten clevis (6) onto piston rod

(2). Clevis should have full thread engagement

with piston rod. Install hex head cap screw (11)

and hex nut (10). Tighten hex nut to 26 lb-ft (35

N.m).

WARNING

Hydraulic

oil

can

be

moderately

flammable and can be an irritant to

the

skin,

eyes,

and

respiratory

system. Avoid prolonged exposure.

Eye protection and rubber gloves

must be worn when working with

hydraulic oil.

b.

Lubricate chrome surface of piston rod (2) with

clean hydraulic oil. Rotate and slide cylinder

head (3) onto piston rod.

CAUTION

Be careful not to damage preformed

packing when sliding over threads.

Sharp edges of thread can cut or

damage

preformed

packing.

Damaged

preformed

packing

will

cause

leakage

and

affect

performance.

c.

Install preformed packing (9). Ensure preformed

packing is seated against shoulder on piston rod

(2).

d.

Install piston (8) on piston rod (2). Make sure

packing seat on face of piston slides over

installed preformed packing (9) without pinching.

CAUTION

Do not clamp piston rod against

metal jaws of bench vise. Damage to

chrome surface of piston rod can

result from contact with metal vise

jaws.

e.

Clamp clevis (6) in bench vise.

CAUTION

Make sure preformed packing (9)

does not get pinched between piston

rod (2) and piston (8) when tightening

lock nut (7). Packing will not seal

properly if pinched.

f.

Install and tighten lock nut (7) to 130 lb-ft (176

N•m).

g.

Remove assembled components from bench

vise.

GO TO NEXT PAGE

2-697