TM 5-3895-373-34

B.

ADJUST.

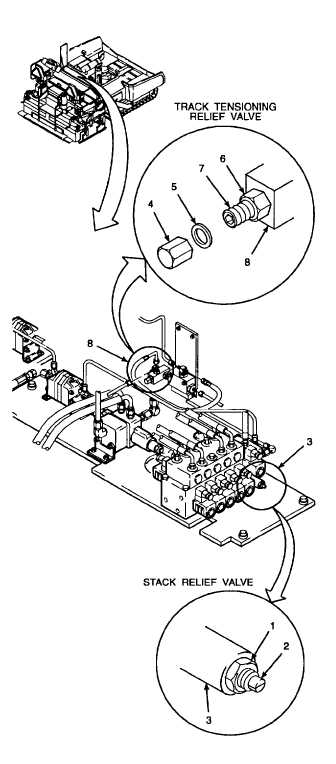

NOTE

Valves are illustrated as located on

the paving machine for on-machine

adjustment.

Valve

settings

are

measured using hydraulic systems

test and repair tool outfit. Refer to

TM 9-4940468-14 for procedures.

Before adjusting a valve installed on

the machine, you should perform

equipment setup per step A.2.

1.

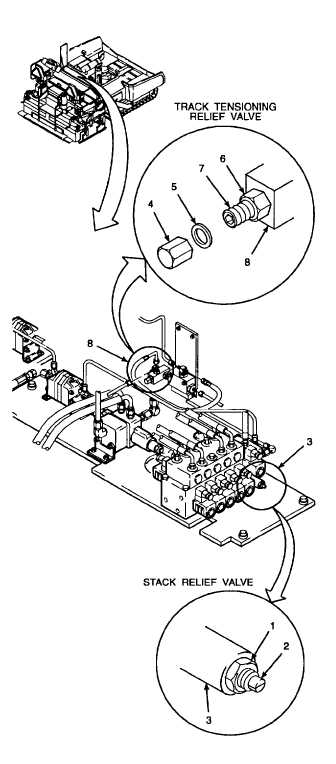

ADJUST STACK RELIEF VALVE.

a.

Loosen jam nut (1).

b.

Turn adjustment screw (2) clockwise to increase

relief valve setting

or

counterclockwise

to

decrease relief valve setting.

c.

Set stack valve safety relief valve (3) to 2500 psi

(17 238 kPa).

d.

Tighten jam nut (1). Ensure adjustment screw

(2) does not turn while tightening jam nut.

e.

Recheck pressure setting.

2.

ADJUST TRACK TENSIONING RELIEF VALVE.

NOTE

Before adjusting track tensioning

relief pressure while the valve is in

the machine, loosen hex nut and turn

adjustment screw on track tensioning

unloading valve clockwise until it is

all the way in. Refer to step 3.b.

a.

Remove cap nut (4) and flat washer (5).

b.

Loosen hex nut (6).

c.

Turn adjusting screw (7) clockwise to increase

relief pressure setting or counterclockwise to

decrease relief setting. Ensure stack valve relief

pressure is set to 2500 psi (17 238 kPa) per step

l.c.

d.

Set track tensioning relief valve (8) to 1800 psi

(12 411 kPa).

f.

Recheck pressure setting.

e.

Tighten hex nut (6). Ensure adjusting screw (7)

does not turn while tightening hex nut. g. Install

flat washer (5) and cap nut (4). Tighten cap nut.

GO TO NEXT PAGE

2-685