TM 5-3895-373-34

D.

INSPECT.

1.

INSPECT GEARS FOR BURRS, SCORING, AND

WEAR.

a.

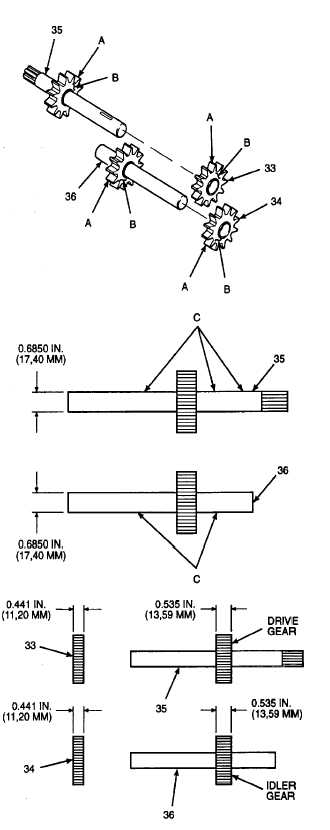

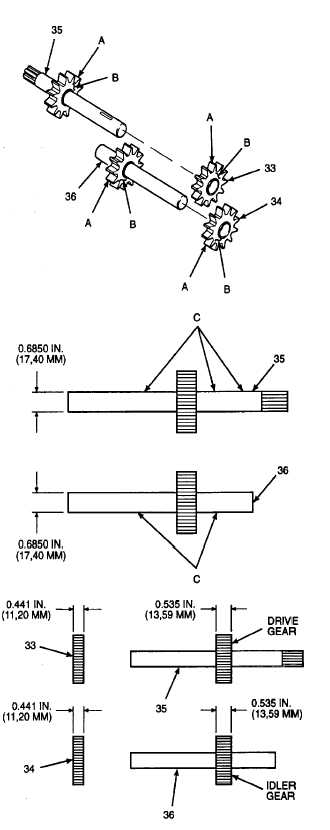

Visually inspect drive gear (33), idler gear (34),

drive gear assembly (35), and idler gear

assembly (36) gears, surfaces A, for burrs.

Inspect gear surfaces B for scoring.

b.

Use emery cloth to smooth any burrs on gear

teeth. Clean gears and shafts after polishing.

Refer to cleaning procedure.

c.

Use emery cloth to remove scoring that can be

felt with a fingernail on gears. Clean gears and

shafts after polishing. Refer to cleaning

procedure.

d.

Replace drive and idler gear assemblies (35 and

36) or drive and idler gears (33 and 34) if burrs

or scoring cannot be removed or if gear teeth are

worn to a point.

2.

INSPECT DRIVE SHAFT AND IDLER SHAFT FOR

WEAR.

a.

Use an outside micrometer to measure shaft

diameters C of bearing journals on drive gear

assembly (35) and idler gear assembly (36).

b.

If bearing journal diameter is less than 0.6850 in.

(17, 40 mm) replace gear assembly.

3.

INSPECT DRIVE AND IDLER GEAR WIDTHS FOR

WEAR.

a.

Use an outside micrometer to measure drive

gear (33) and idler gear (34) width. If gear width

is less than 0.441 in. (11, 20 mm), replace drive

gear and idler gears.

b.

Use an outside micrometer to measure drive

gear assembly (35) gear width and idler gear

assembly (36) gear width. If gear width is less

than 0.535 in. (13, 59 mm) replace gear

assembly.

c.

Inspect drive spline of drive gear assembly (35)

for cracks, chips, or wear steps. Replace gear

assembly if drive spline is worn or damaged.

GO TO NEXT PAGE

2-573