TM 5-3895-373-34

C.

CLEAN Continued.

2.

CLEAN THREADED FASTENERS.

Thread locking compound solvent can

cause eye damage. Wear safety

goggles/glasses when using. Avoid

contact with eyes. If solvent contacts

eyes, flush eyes with water and get

immediate medical attention.

a.

Rinse threaded fasteners with thread locking

compound solvent.

b.

Dry fasteners with cleaning cloths.

D.

INSPECT.

1.

INSPECT GEARS AND SPLINES.

a.

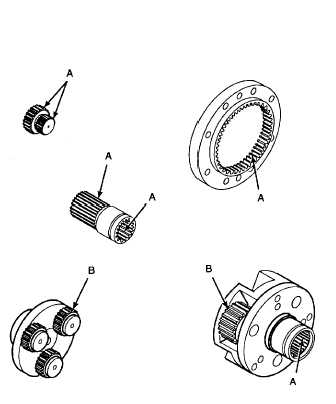

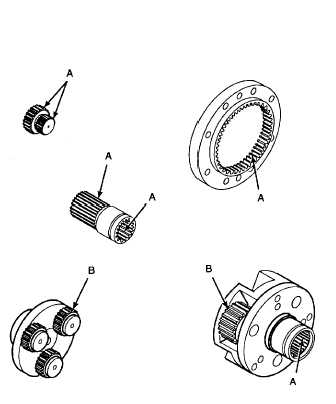

Visually inspect gear and spline teeth A for

cracks, chips, and wear. Replace mating

gearsets if gear or spline teeth are worn or

damaged.

b.

Rotate gears B to check for bearing damage.

Replace gear assembly if bearing rotation feels

rough or if all bearings do not spin freely.

2.

INSPECT COMPONENT SURFACES AND

PACKING GROOVES.

a.

Inspect preformed packing grooves C, packing

seats D, and seal seats E for sharp edges or

burrs caused by nicks, scratches, or dents.

Remove sharp edges or burrs with crocus cloth.

b.

Visually inspect all component surfaces for

indications of cracks, chipping, or breaks.

Replace

cracked,

chipped,

or

broken

components.

c.

Inspect all machined mating surfaces for raised

edges caused by nicks, scratches, or dents.

Remove raised material with crocus cloth.

GO TO NEXT PAGE

2-481