TM 5-3895-373-34

Table 2-2. Track Tension Troubleshooting - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1.

TRACK FAILS TO MAINTAIN OPERATING TENSION - Continued.

Step 2.

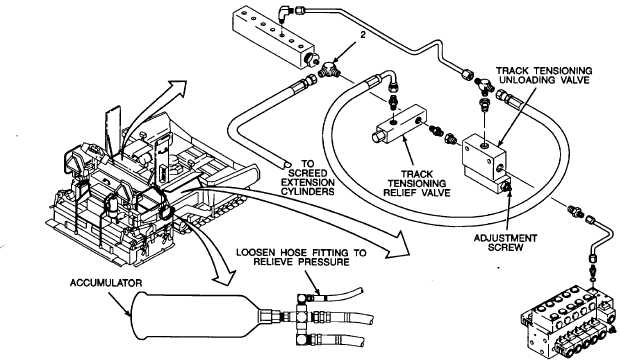

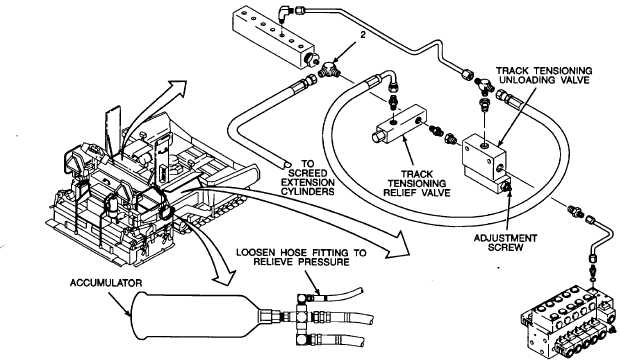

Open center top right and center top left access doors per TM 5-3895-373-10. Open right access

door per TM 5-3895-373-10. Check track tensioning relief valve setting of track tension relief.

WARNING

Hydraulic oil can be moderately flammable and can be an irritant to skin, eyes, and respiratory system. Avoid

prolonged exposure. Eye protection and rubber gloves must be worn when working with hydraulic oil.

Relieve system pressure by loosening hose fitting at accumulator before installing hydraulic system

tester at port (2). Install hydraulic system tester for pressure test at port (2) per TM 9-4940-468-14.

To check relief valve, turn track tensioning unloading valve adjustment screw all the way in to obtain

maximum pressure. With paving machine at high idle, track tensioning relief valve should unload at

1800 psi (12 411 kPa). After checking relief valve setting, turn engine off and relieve system

pressure by loosening hose fitting at accumulator. Tighten fitting and adjust unloading valve

adjustment screw to reset system pressure to 900 psi (6205 kPa).

If relief lifts below 1800 psi (12 411 kPa), or is stuck open, adjust track tensioning relief valve per

paragraph 2.51, or replace/repair per paragraph 2.38.

If track tension relief functions properly, replace/repair track tensioning unloading valve per 2.38.

2-18