TM 5-3895-373-34

Table 2-3. Propulsion System Troubleshooting - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1.

TRACK FAILS TO MOVE OR MOVES SLUGGISHLY- Continued.

Step 2.

Check if one brake releases by engaging track drive with control handle.

If one brake releases, replace/repair brake not releasing per paragraph 2.33. Go to step 4.

WARNING

Hydraulic oil can be moderately flammable and can be an irritant to skin, eyes, and respiratory

system. Avoid prolonged exposure. Eye protection and rubber gloves must be worn when working

with hydraulic oil.

Step 3.

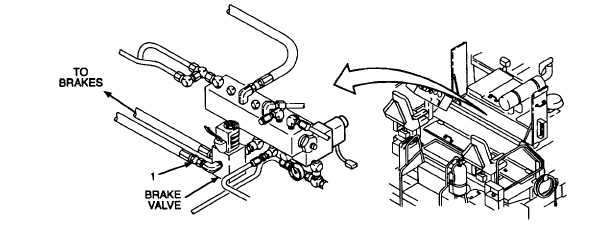

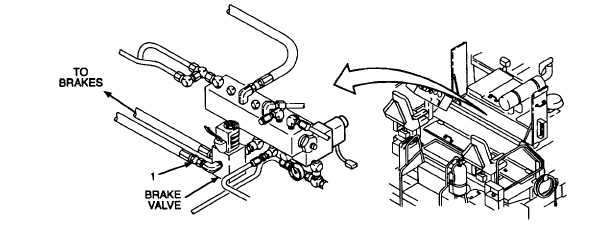

Open center top right and center top left access doors per TM 5-3895-373-10. Install hydraulic

system tester at inlet (1) for pressure test per TM 9-4940-468-14. Check pressure at brake valve

inlet (1) with brake valve energized. Pressure at brake valve inlet should be greater than 135 psi

(931 kPa).

If brake valve inlet pressure is greater than 135 psi (931 kPa), replace/repair brake valve per

paragraph 2.28.

If brake valve inlet pressure is less than 135 psi (931 kPa), replace/repair left hand hydraulic

propulsion pump per paragraph 2.30.

2-24