TM 5-3895-373-34

E.

ASSEMBLE - Continued.

3.

REASSEMBLE PISTON ROD.

Do not clamp piston rod against metal jaws

in vise. Use vise jaw caps between vise jaws

and piston rod. Damage to chrome surface

of piston rod can result.

a.

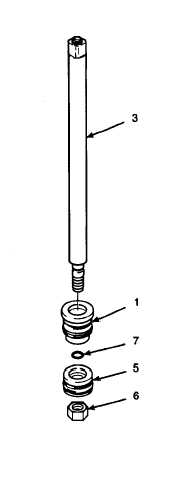

Clamp piston rod (3) in a bench vise on

square end. Pad vise jaws with vise jaw

caps.

New seals and preformed packings are

distorted

during

installation.

Allow

a

minimum

of

one

hour

for

seals

and

preformed packings to conform to original

shape before installing cylinder head and

piston on rod. Bypass leakage can result

from poor installation.

b.

Allow one hour for seals and preformed

packings to conform to original shape.

Hydraulic oil can be moderately flammable

and can be an irritant to the skin, eyes, and

respiratory

system.

Avoid

prolonged

exposure. Eye protection and rubber gloves

must be worn when working with hydraulic

oil.

c.

Lubricate

piston,

cylinder

head,

and

preformed packing with clean hydraulic oil.

d.

Install cylinder head (1) onto piston rod (3).

Slide cylinder head down length of piston

rod.

Be

careful

not

to

damage

preformed

packings when sliding over threads. Sharp

edges

of

threads

can

cut

or

damage

preformed packings. Damaged preformed

packings will cause leakage and affect

performance.

e.

Install preformed packing (7) onto piston

rod. Ensure preformed packing seats in

groove on rod (3).

f.

Slide piston (5) onto piston rod (3).

g.

Have a second person support unclamped

end of the piston rod and install self-locking

hex nut (6) onto threaded end of rod.

Tighten to 200 lb-ft (271 N•m) using socket

wrench adapter.

h.

Remove piston rod from bench vise.

GO TO NEXT PAGE

2-1045