TM 5-3895-373-20

1.11.

CHARACTERISTICS,

CAPABILITIES,

AND

DATA.

The paving machine is a turbosupercharged, 4-cylinder,

diesel powered, hydraulically driven tracked vehicle.

The engine is coupled to a dual main pump drive

gearbox which drives two propulsion pumps in tandem

with two auxiliary pumps and one auxiliary vibration

pump. The propulsion pumps supply hydraulic pressure

to the track drive motors. The auxiliary hydraulic pumps

are used to operate all controls and cylinder drive

functions.

Control handles on the operator control panel control

each track drive motor located on the undercarriage of

the paving machine. Paving speed is from 0 to 135 fpm

(O to 41 mpm) with travel speed (switch selected) of 0 to

3.2 mph (O to 5, 2 kph). Hydraulic cylinders

automatically maintain tension on the 12-inch wide steel

track pad. A high wear-resistant rubber pad is attached

to each track pad. Spring applied hydraulically released

disc brakes are located between the hydraulic drive

motors and torque hubs. In the event that hydraulic

pressure or electrical power is lost, the brakes are

automatically applied.

Push rollers are located in front of the material hopper

and are designed to ride against the rear wheels of the

paving material haul truck. The push rollers allow the

paving machine to push the haul truck forward, while

continuing to receive material into the hopper and spread

the paving material at the same time. Hopper wings are

hydraulically raised and lowered from the operator

control console. Dual slat conveyors move the paving

material from the hopper to the auger, and are

independently controlled from the operator control

console. Two electric actuators control flow gates that

meter the amount of material conveyed to the augers.

Two 12-inch (304 mm) augers spread the paving

material in front of the screed.

Four diesel fuel-fired burners are located on the screed.

The burners heat the screed plates to approximately

300°F (150°C) to prevent paving material from sticking to

the screed plates. The screed is hydraulically

extendable from 8 to 14 feet (2, 4 to 4, 3 m) and can be

extended further to 16 feet (4, 9 m) with bolt-on screed

and auger extensions. Mechanical adjustments on the

screed control the thickness, slope, and crown of the

paving material. The screed vibrator provides the initial

compaction of the paving material. The amount of

compaction is controlled by the frequency and amplitude

of vibration. Vibration is controlled by the screed

vibration control valve, located underneath the operator

platform on the rear tractor bulkhead.

1.12.

LOCATION AND DESCRIPTION OF MAJOR

COMPONENTS.

The following provides the location and description of

major paving machine components maintained by the

organizational maintenance activity.

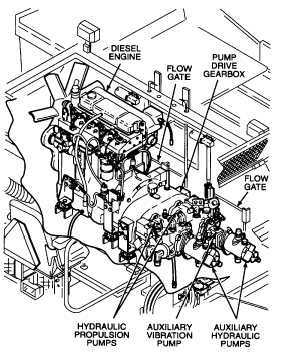

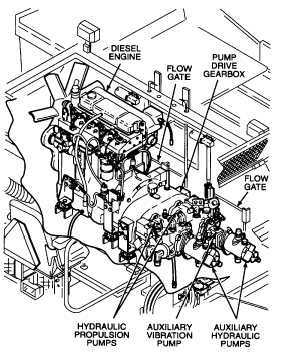

1.12.1. Engine

Compartment.

The

engine

compartment houses the paving machine drive system

and hydraulic power components, air cleaner, filters,

radiator, hydraulic oil cooler, exhaust system, and flow

gates. These components are described as follows:

a. Drive System and Hydraulic Power. The paving

machine drive system includes a turbosupercharged

diesel engine with a pump drive gearbox adapted to the

engine flywheel. Directly coupled to the gearbox drives

are two main hydraulic propulsion pumps. The

propulsion pumps provide hydraulic power to the left and

right track drive motors. Two auxiliary hydraulic pumps,

and one vibration pump are connected to the propulsion

pumps in tandem. These pumps provide hydraulic

power to non-propulsion hydraulic functions needed to

operate the paving machine.

1-3