(w) Correct the direction of paver movement by moving 'the Track Switch of the pivot track to OFF

momentarily.

(x) After some experience is gained with manual feed control, set both Feed Switches to AUTO. and

observe the level of material maintained by the two depth sensors. If necessary, stop paving and re-set each

sensor by loosening the control arm and sliding it inward or outward to maintain a different material height on

the screws.

Adjusting Right Hand Hopper Gate

Figure 3

MATERIAL CONTROL

Adjust hopper gates, Figure 3, so the material flows almost constantly to the spreader screws. The

spreader screws should be kept a little more than half covered with material (Refer to Material Feed,

Section 6)

(1) The ends of the spreader screws should not be filled too full. This causes the material to pack

against the end plates and in some cases may spill over the sides. IMPORTANT: When operating with

automatic feed control, never starve the screw conveyors to the extent that there is not enough material in

the screws for the cut-off switches to operate. It is important to check to see that material does not build up in

switches and control arms, causing improper operation. KEEP CLEAN AT ALL TIMES.

(2) When too much material is carried in the spreader screws, excessive wear will occur on the screws,

and the material will spill over the end plates and screed moldboard.

(3) When operating under manual control the operator will have to watch the material level across the

length of the screed because uneven or excessive amounts of material cause a poor appearing and wavy mat.

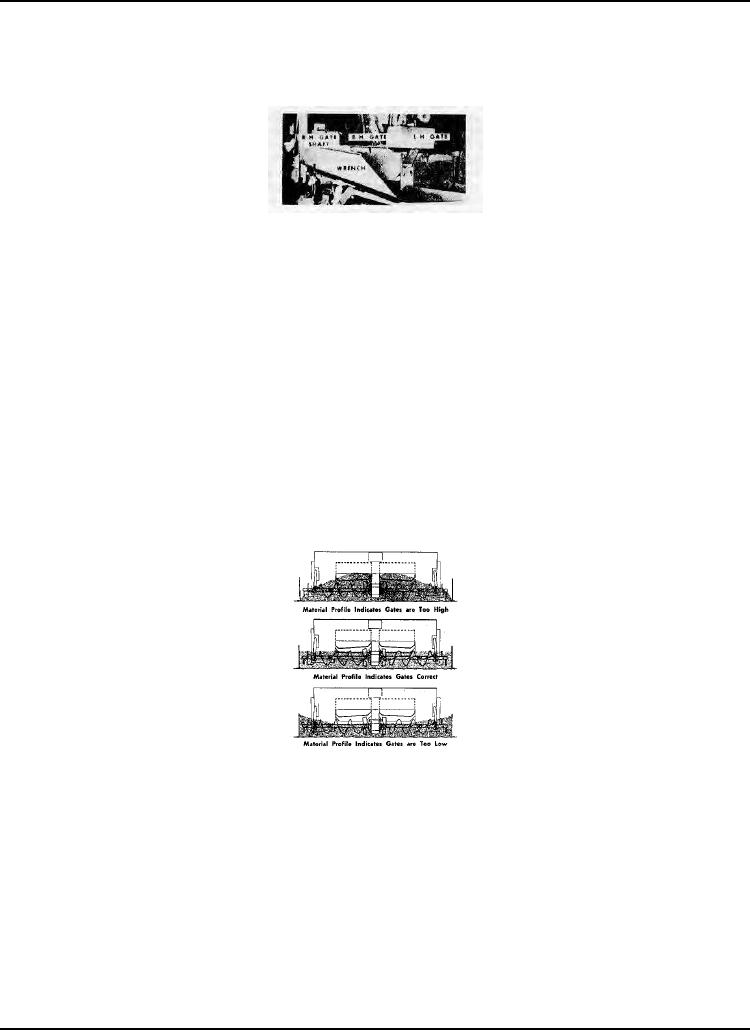

ADJUSTMENT OF HOPPER GATES

The material gates, Figure 4, located to the rear of the hopper, control the flow of material to the spreader

screws.

(1) Gates should be regulated so that the spreader screws operate 80% (minimum) of the time.

Comparison of Gate Height to Material Feed

Figure 4

(2) When bleeding out material on one side of paver, the operator should and may have to adjust the

gate on that side to increase the amount of material flowing to the spreader screws. Switch from automatic to

manual feed.

OPERATING SUGGESTIONS

(1) Mat Thickness - The screed man should check the depth being laid at each side of the mat and

make whatever adjustments necessary to maintain a uniform depth of mat.

(2) The adjustment of the screed control should not be made too rapidly. The screed should always be

allowed to seek the new level of operation.

(3) The operator should make sure that the proper amount of material is being fed to the spreader

screws.

(4) The operator should check the speed the paver is traveling. The paver should move fast enough to

lay the material without delaying the trucks, and not so fast that he has to wait for trucks.

(5) The operator should never run the slat conveyors out of material and starve the spreader screws,

but he should allow the hopper to empty out to some extent before the next truck dumps its material.

Page 81