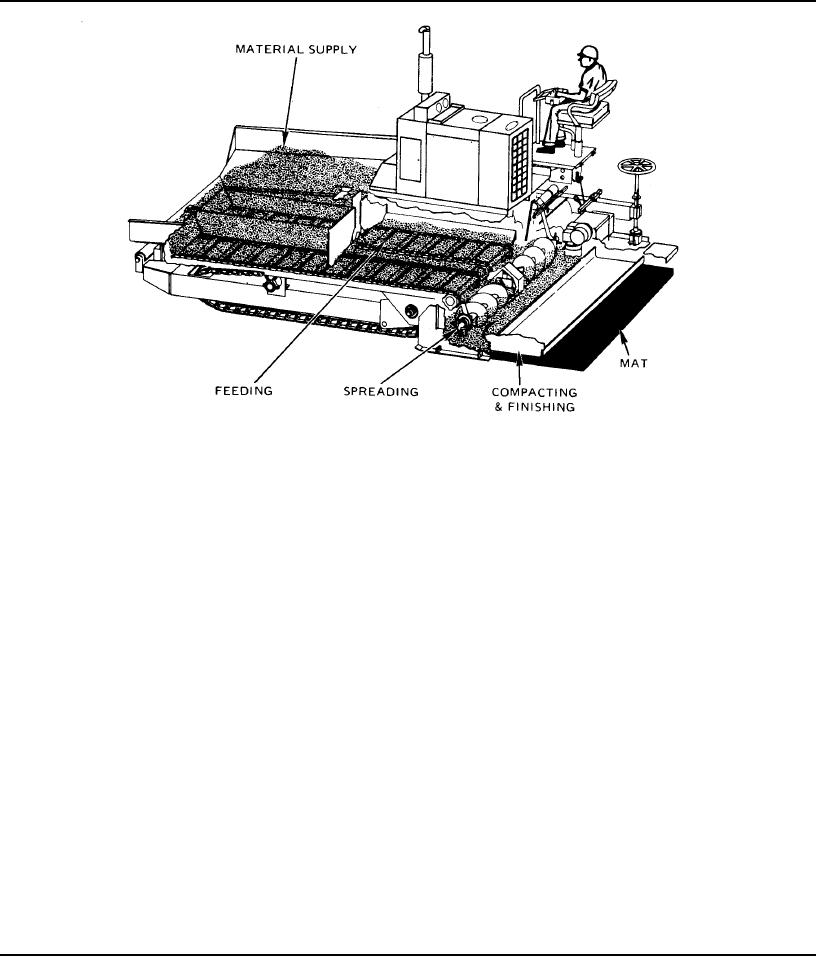

Figure 9. Material Flow Diagram

FUNCTION AND APPLICATION

The Cedarapids crawler mounted paver is designed to lay a uniform high density mat of asphalt material on

highways, roadways, airport-runways, parking lots and driveways. It is cap able of performing jobs having strict control

specifications and high production requirements. The paver will level and compact asphalt material up to 10 inches in

depth, with mat widths varying from 6 to 20 feet. Mat depth and width variations are accomplished by adjustment of feed

controls and by arrangement and adjustment of the finishing and compacting device called the "Screed."

The uniformly mixed, hot asphalt material is dumped by truck loads onto the hopper of the paver at a rate suitable

for spreading and finishing. During this unloading process the paver contacts the rear wheels of the truck and pushes the

vehicle ahead with it's own power as the paving progresses.

The hot material from the hopper is metered by two separate slat conveyors to the two spreading screws which are

at the rear of the tractor unit and ahead of the screed. The feed of material may be either manually or automatically

regulated to obtain a properly proportioned distribution. The attached "screed" assembly which is a full floating unit drawn

by the tractor, "rides up" on the asphalt to the degree set on the adjustable controls and in so doing varies the thickness

and contour of the mat deposited beneath it. The screed controls can be adjusted either manually or automatically to

create a new surface which is minus the undesirable irregularities of the old. The screed unit which performs the "ironing"

job on the asphalt is equipped with electric vibrators which assist in the initial compaction and smoothing of the high

density mat.

Final compaction of the newly laid asphalt mat is accomplished by separate rolling equipment according to

established compaction specifications.

The paver screed can be fitted with special attachments for paving of highway shoulders which are not simple

extensions of the roadway. Numerous cut-off and beveling attachments meet the need for varying width and contour

requirements.

The screed is equipped with an oil or gas fired heater which is operated prior to paving in order to bring the screed

temperature up to the temperature of the asphalt, so that no sticking and dragging will occur.

The raising and lowering of the full floating screed for either paving or travel is done hydraulically by toggle switch

control.

Page 7