Engine Tune-Up

pin in the throttle shaft assembly entering the slot in the differential lever.

b.

Install the four cover screws and lock washers finger tight.

c.

Pull the cover assembly in a direction away from the engine, to take up the slack, and tighten the cover

screws.

NOTE: This step is required since no dowels are used to locate the cover on the housing.

Position Injector Rack Control Levers

The position of the injector control rack levers must be correctly set in relation to the governor. Their position determines

the amount of fuel injected into each cylinder and ensures equal distribution of the load. Properly positioned injector

control rack levers with the engine at full-load will result in the following:

1.

Speed control lever at the maximum speed position.

2.

Stop lever in the RUN position.

3.

Injector fuel control racks in the full-fuel position.

Adjust the rear injector rack control lever first to establish a guide for adjusting

the remaining levers.

1.

Loosen all of the inner and outer injector rack control lever adjusting screws

(Fig. 2). Be sure all of the levers are free on the injector control tube.

2. Move the speed control lever to the maximum speed position.

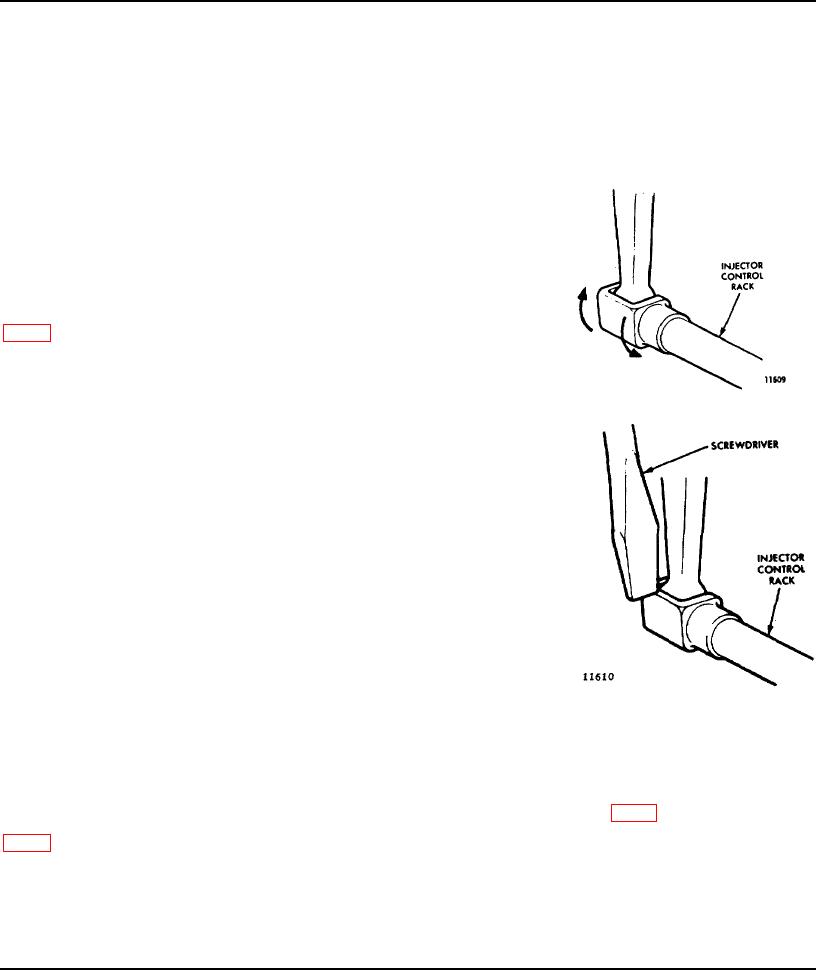

Fig. 3 - Checking Rotating Movement of Injector Control Rack.

3. Move the stop lever to the RUN position and hold it in that position with light

finger pressure. Turn the inner adjusting screw of the rear injector rack

control lever down until a slight movement of the control tube is observed or

a step-up in effort to turn the screw driver is noted. This will place the rear

injector rack in the full-fuel position. Turn the outer adjusting screw down

until it bottoms lightly on the injector control tube. Then alternately tighten

both the inner and outer adjusting screws. This should result in placing the

governor linkage and control tube in the respective positions that they will

attain while the engine is running at full load.

NOTE: Overtightening of the injector rack control lever adjusting screws

during installation or adjustment can result in damage to the injector

control tube. The recommended torque of the adjusting screws is 24-36

in-lbs (3-4 Nm).

Fig. 4 - Checking Injector Control Rack "Spring"

4.

To be sure of proper rack adjustment, hold the stop lever in the RUN position and press down on the injector rack

with a screw driver or finger tip and note "rotating" movement of the injector control rack (Fig. 3). Hold the stop lever in

the RUN position and, using a screw driver, press downward on the injector control rack. The rack should tilt downward

(Fig. 4) and, when the pressure of the screw driver is released, the control rack should "spring" back upward.

If the rack does not return to its original position, it is too loose. To correct this condition, back off the outer adjusting

screw slightly and tighten the inner adjusting screw. The setting is too tight if, when moving the stop lever from the

STOP to the RUN position, the injector rack becomes tight before the stop lever reaches the end of its travel. This will

result in a step-up in effort

Page 96