TM 5-3895-385-10

0003

Track Tension

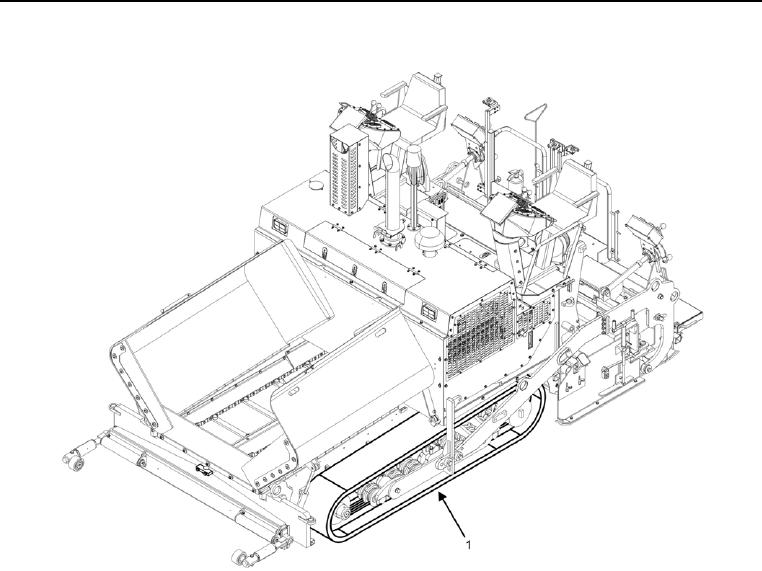

Figure 6. Self-Tensioning Drive Track.

The self-tensioning track hydraulic cylinder operates between 250 1,500 pounds per square inch (psi) (113.5

681 kilograms (kg) per square inch) using a pressure-compensating pump. A pressure-reducing valve is installed

in the track tension manifold to maintain pressure at the recommended 900 psi (408.6 kg per square inch). The

continuous rubber tracks are independently controlled by joysticks located on the control pedestal. The rubber

track (Figure 6, Item 1) is mounted on a structural steel frame and undercarriage.

All structural components within the undercarriage and steel frame are inspected and measured for square and

perpendicular trueness to ensure optimum rubber track life. The floating bogie assembly allows uneven terrain to

be absorbed into the track system (controlled flexing) while maintaining continuous track tension. The track

system also has one of the lowest ground pressures for this class of BMPM.