TM 5-3895-373-34

2.10

SCREED LIFT SYSTEM.

Table 2-5 lists common malfunctions associated with the

screed lift system that may be found during operation or

maintenance of the paving machine. Perform the tests/

inspections and corrective actions for a particular

malfunction in order given.

This table cannot list all possible malfunctions that may

occur, nor all tests, inspections, or corrective actions. If

a malfunction is not listed, or is not corrected by listed

corrective actions, notify your supervisor.

Table 2-5. Screed Lift System Troubleshooting.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1.

SCREED FAILS TO LIFT.

Step 1.

Check operation of hopper lift cylinders and screed extension cylinders.

If hopper lift cylinders and screed extension cylinders operate normally, go to step 2.

If hopper lift cylinders and screed extension cylinders fail to operate normally, go to step 3.

WARNING

Hydraulic oil can be moderately flammable and can be an irritant to skin, eyes, and

respiratory system. Avoid prolonged exposure. Eye protection and rubber gloves must

be worn when working with hydraulic oil.

NOTE

The following tests require use of a hydraulic system tester. Install tester in-line at

flow test point indicated by each individual test per TM 9-4940-468-14. Make sure

ratings of all fittings and hoses used are adequate for maximum pressures and flows

being tested.

NOTE

System operating pressure must be at 2475 ±25 psi (17 066 +172 kPa) before

performing this test. If pressure is not correct, refer to paragraph 2.51 and reset

system operating pressure.

Step 2.

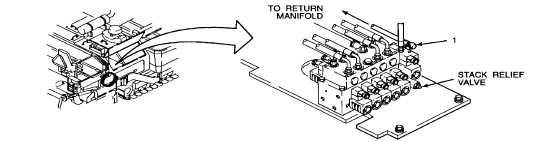

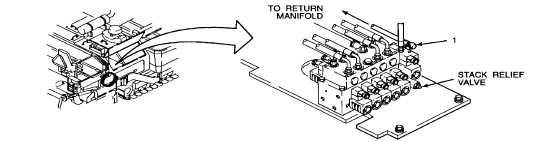

Open right access door per TM 5-3895-373-10. Install hydraulic system tester for flow test at port

(1) per TM 9-4940-468-14. With screed lift switch in lift position, check for flow from stack relief

valve to return manifold at port (1).

If flow is present, replace stack relief valve per paragraph 2.44.

If flow is not present, refer to MALFUNCTION 4. AUXILIARY HYDRAULIC SUPPLY TO VIBRATION AND

CYLINDER CIRCUITS FAULTY.

2-36