TM 5-3895-373-34

Table 2-4. Tow Point Lift System Troubleshooting - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1.

TOW POINT CYLINDERS DO NOT OPERATE-Continued.

WARNING

Hydraulic oil can be moderately flammable and can be an irritant to skin, eyes, and

respiratory system. Avoid prolonged exposure. Eye protection and rubber gloves must be

worn when working with hydraulic oil.

Step 3.

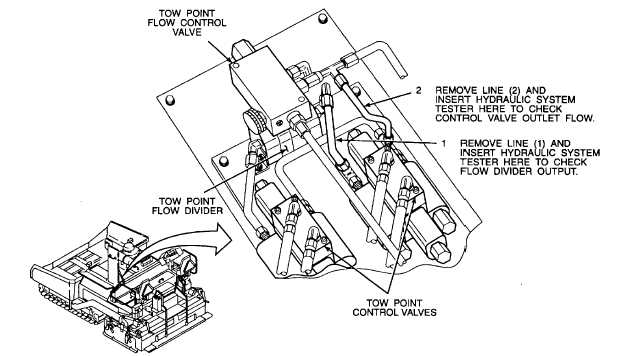

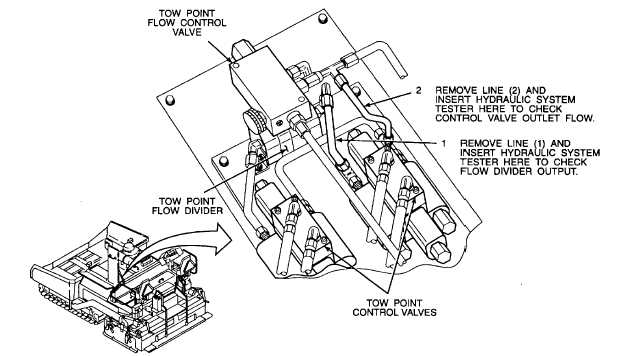

Install hydraulic system tester at inlet (1) for flow test per TM 9-4940-468-14. Open center top right

and center top left access doors per TM 5-3895-373-10. Open left access door per TM 5-3895-373-

10. Check maximum flow rate at tow point flow divider outlet to control valve inlet (1).

If flow is less than 1 gpm (3, 8 l/min) or more than 2 gpm (7, 6 l/min) replace tow point flow

divider per paragraph 2.55 and repair per paragraph 2.49.

Step 4.

Disconnect hydraulic system tester per TM 9-4940-468-14. Reconnect all hydraulic lines. Close left

access door per TM 5-3895-373-10. Close center top left and center top right access doors per TM

5-3895-373-10.

2.

ONE TOW POINT CYLINDER FAILS TO OPERATE.

Replace tow point control valve per paragraph 2.55 and repair per paragraph 2.46.

2-34