TM 5-3895-373-34

2.40

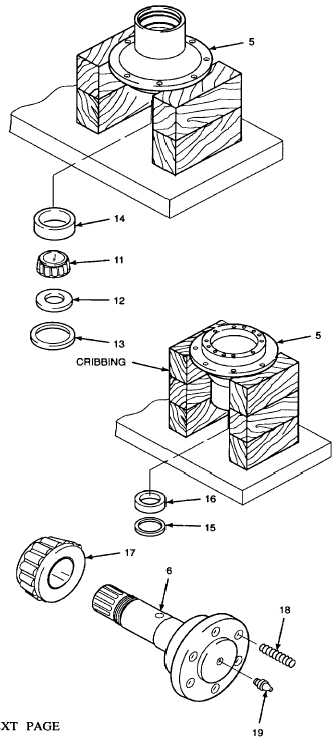

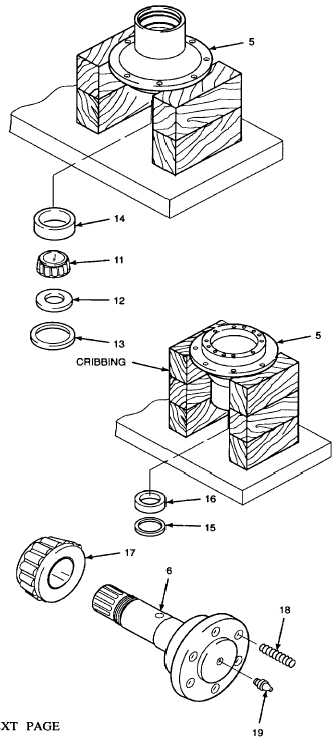

REPLACE/REPAIR TRACK DRIVE HUB - Continued.

A.

REMOVE - Continued.

4.

REMOVE

REMAINING

BEARING

COMPONENTS, FLAT WASHER, PLAIN SEAL,

NONMETALLIC

SEAL,

DRIVE

SPROCKET

GEAR

MOUNTING

STUDS,

AND

LUBRICATION FITTING.

a.

Set track drive hub (5) on cribbing, large flange

down. Use brass drive pin punch and hammer

to drive out tapered roller bearing (11), flat

washer (12), and plain seal (13). Discard

encased plain seal and tapered roller bearing.

b.

Carefully and evenly drive tapered roller cup (14)

from track drive hub (5). Discard tapered roller

cup.

c.

Set track drive hub (5) on cribbing, large flange

up. Allow at least 1 in. (25 mm) clearance

between track drive hub and surface of work

bench.

d.

Using brass drive pin punch and plastic hammer,

tap evenly around full perimeter of nonmetallic

seal (15). Drive nonmetallic seal out of track

drive hub (5). Discard nonmetallic seal.

e.

Repeat procedure in step d to remove tapered

roller cup (16). Discard tapered roller cup.

f.

Using universal puller kit, pull tapered roller

bearing (17) from drive shaft hub (6). Discard

tapered roller bearing.

g.

Using stud remover and setter, remove drive

sprocket gear mounting studs (18) from hub

drive shaft (6). Remove lubrication fitting (19).

Discard drive sprocket gear mounting studs and

lubrication fitting.

GO TO NEXT PAGE

2-548