TM 5-3895-373-34

Table 2-1. Engine Troubleshooting - Continued.

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1.

ENGINE FAILS TO START OR FAILS TO START EASILY Continued.

NOTE

A drop in engine speed caused by loosening fuel line supplying fuel injector indicates the

injector was delivering fuel to cylinder. If engine speed is not affected by loosening fuel

line supply to fuel injector, fuel injector is faulty.

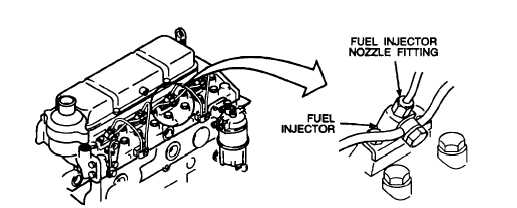

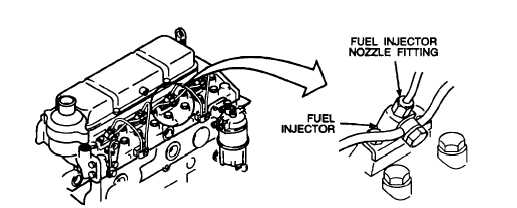

If the engine does not start easily; once the engine is operating, loosen a fuel line at one

fuel injector nozzle fitting. Listen for a change in engine speed. Check the injector for

each cylinder until faulty fuel injector is found.

If a fuel injector is determined faulty, adjust or replace fuel injectors as necessary per paragraph 2.18.

If replacement of a faulty fuel injector does not correct malfunction, or is not out of adjustment,

replace/repair fuel injection pump per paragraph 2.19.

Step 4.

Check adjustment and timing of intake and exhaust valves per TM 5-3895-373-20.

Adjust intake and/or exhaust valves per TM 5-3895-373-20.

Step 5.

Check for balanced engine compression per TM 9-4910-571-12&P.

If engine fails compression unbalance test, compression is below 300 psi (2068 kPa) or varies *25

psi (172 kPa) between cylinders, refer to MALFUNCTION 9. POOR COMPRESSION.

Step 6.

Inspect intake and exhaust valves, push rods, springs, and guides. Refer to paragraph 2.17.

Replace or repair intake/exhaust valves and valve seat inserts showing signs of pitting.

Replace push rods, springs, and guides as necessary. Refer to paragraph 2.17.

Step 7. Close front top left access door per TM 5-3895-373-10.

2-8