TM 5-3895-373-20

REFERENCE INFORMATION

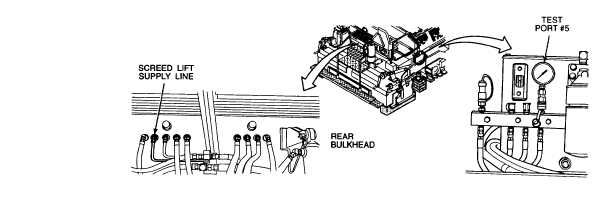

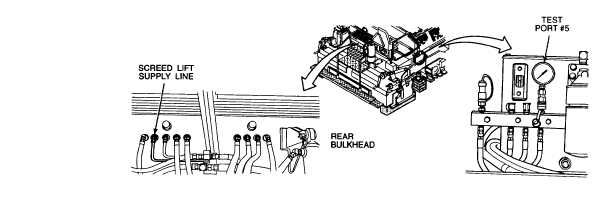

HYDRAULIC CYLINDER CIRCUITS

TEST

PORT #5

SCREED LIFT CYLINDERS - PRESSURE CHECK PROCEDURE

1.

With engine running at MAX speed, lift screed to

fully-raised position. Place cribbing below both

ends of main screed, leaving 1 to 1-1/2 in. air

gap between screed plate and cribbing.

2.

Support screed in fully-raised position with

hydraulic jacks at rear flanges of screed tow

arms.

3.

Turn paving machine off. Use hydraulic jacks to

adjust screed height so that screed lift cylinder

clevis pins turn freely in cylinder mounting

knuckles.

Make sure lift cylinders are not under

load before removing hydraulic hoses

from lift cylinder retract ports. Hydraulic

oil under pressure can penetrate skin or

damage eyes.

4.

Make sure lift cylinders are not under extension

or compression load. Disconnect hoses from

bottom (retract) port elbows of screed lift

cylinders. Plug hose ends and cap off cylinder

retract port elbows; use #6 JIC (9/6-18) high

pressure caps.

NOTE

When hydraulic jack is lowered, screed is expected to

drop slightly. This initial drop will make up for fluid loss

that occurred during removal of supply hoses from

cylinders.

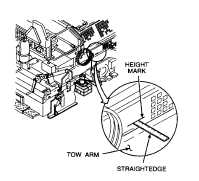

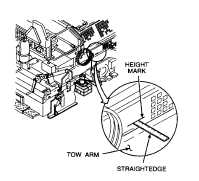

5.

Release both hydraulic jacks at the same time.

When screed is stable, use straightedge and

pencil to mark vertical position of left and right

tow arms.

6.

After 1/2 hour, mark settled position of screed

tow arms. Measure distance between upper and

lower pencil marks on left and right side of

screed. Answer question in paragraph B5 of

flowchart.

7.

Support screed in raised position with hydraulic

jacks at rear flanges of screed tow arms. Adjust

screed height to remove load from screed lift

cylinders.

8.

Remove plugs and caps and reconnect screed

lift cylinder hoses.

After completing diagnostic checks, close right, center

top left, and center top right access doors per TM 5-

3895-373-10.

2-275